The Museum is working with six UK universities and Diamond Light Source on a multidisciplinary study investigating solutions for the extraction of cobalt from ore deposits in Europe.

We hope to increase the UK's exploration, mining and recovery of cobalt, a metal of great strategic and economic importance. In this project we wil look at the geology, geometallurgy and geomicrobiology of cobalt resources leading to new product streams (CoG3).

The project aims to:

- identify new environmentally benign extraction and recovery processes for cobalt

- understand how cobalt minerals and ores are formed

- understand how cobalt behaves in the Earth's crust

- promote a greater understanding of the distribution and behaviour of cobalt in natural systems

Rationale

Cobalt (Co) is classified as an E-tech element by the National Environmental Research Council (NERC) which means it is considered essential for a technologically advanced, low-carbon society. Cobalt is designated a critical element by the European Union's Raw Materials Initiative.

Around 55,000 tonnes of Co are produced globally each year. Less than 0.1 % of this is produced within Europe, yet European countries use around 30 % of globally produced cobalt.

Large untapped reserves of cobalt in Europe include:

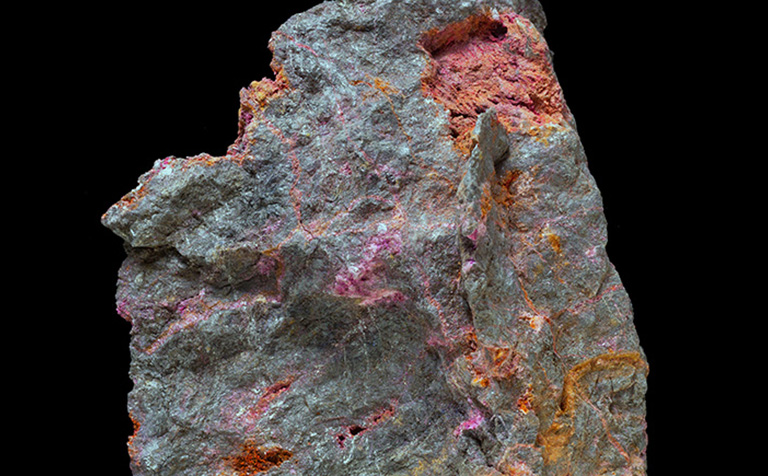

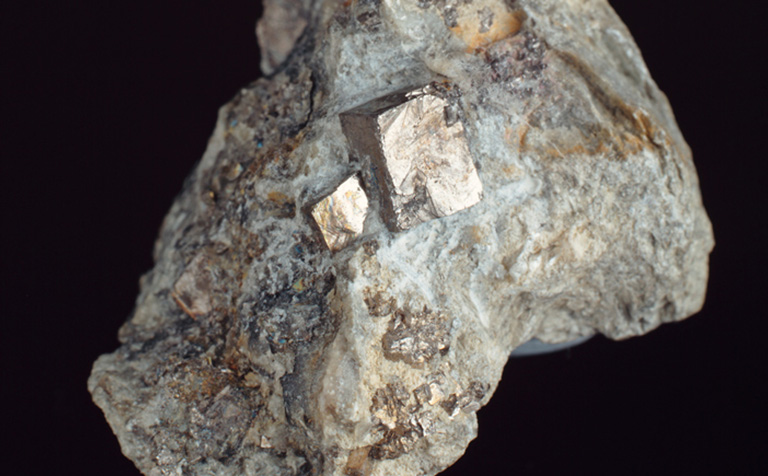

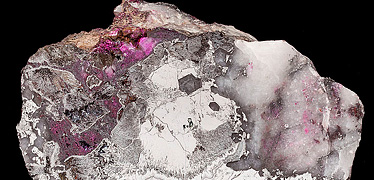

- black shale ores in Poland, which are mined for copper

- cobalt-bearing nickel laterite ores in Greece, Macedonia and Kosovo

Recovery and extraction problems

One of the primary difficulties facing cobalt recovery from sulphide copper ores relates to its flotation when using conventional processes.

In an attempt to overcome these difficulties, processing companies are using increasingly complex chemical additives. The toxicity of these chemicals increases the potential environmental risk of the process, both in terms of volatilisation and leakage into the surroundings.

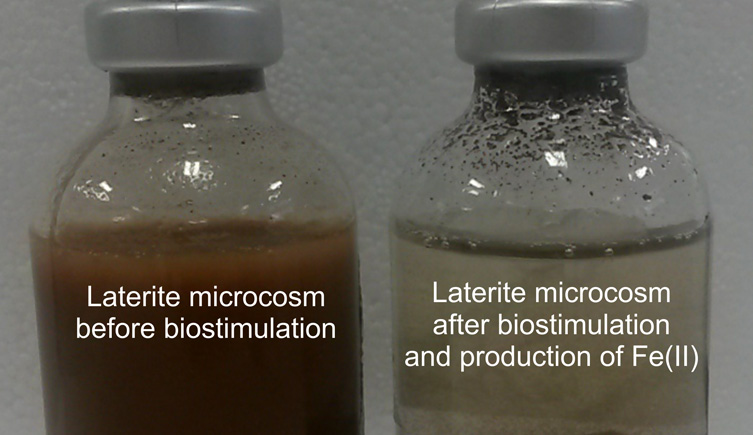

Lateritic and other oxidised cobalt-bearing ores, such as marine nodules, pose significant technical challenges in developing economic and environmentally benign approaches to cobalt recovery.

Recent advances in bioprocessing ores and mineral concentrates have highlighted potential new techniques.